Aug . 07, 2025 04:20 Back to list

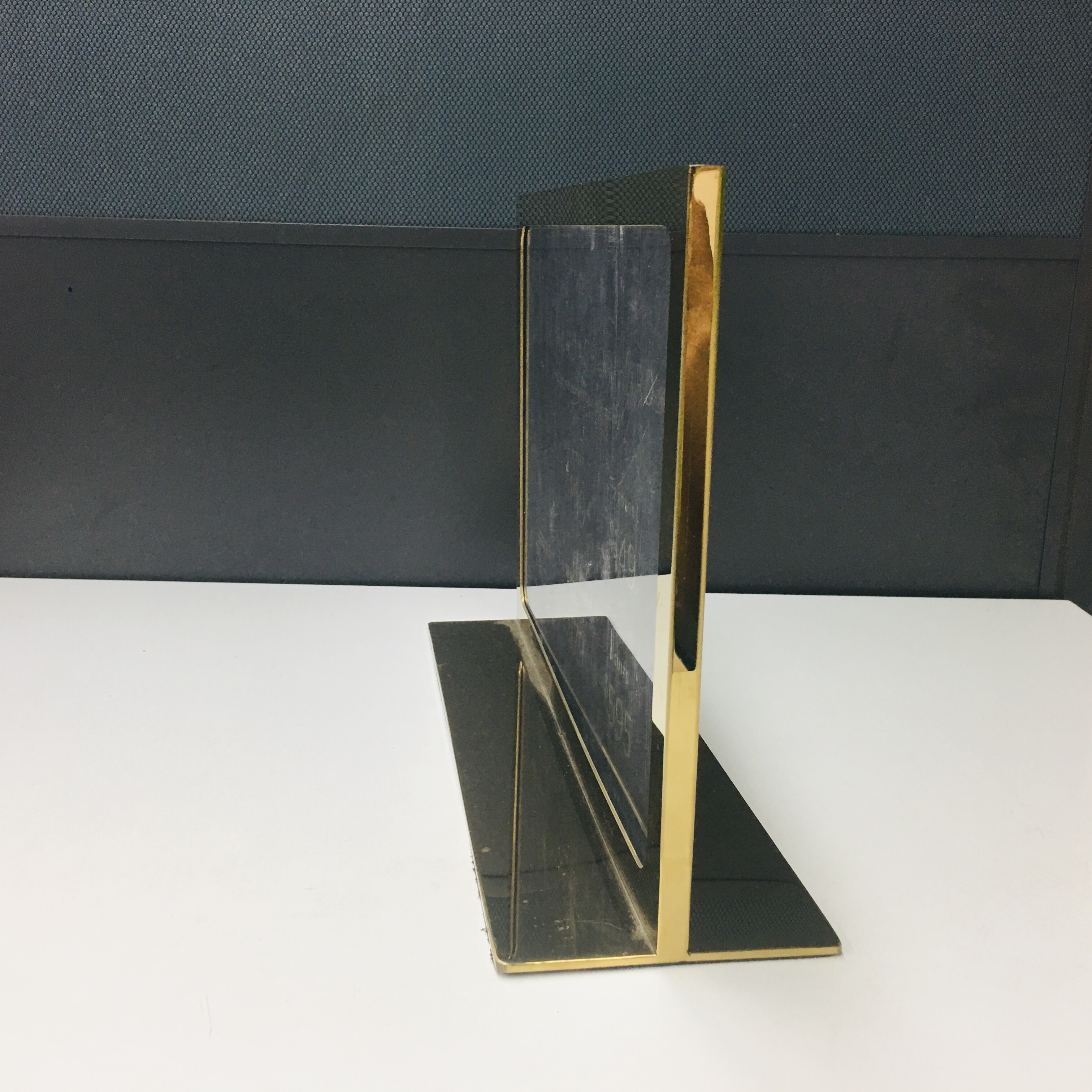

Premium T-shape Acrylic Metal A4 Paper Display Holder

In today's fast-paced commercial and informational environments, effective communication relies not only on the content but also on its presentation. The **T-shape acrylic metal A4 paper holder** stands out as a prime example of how thoughtful design, robust materials, and precision engineering converge to create an indispensable display solution. From retail spaces and corporate offices to public institutions and exhibition halls, this versatile holder provides an elegant, durable, and highly functional means of showcasing A4-sized documents, advertisements, menus, or information notices. Its distinctive T-shape profile ensures stability and dual-sided visibility, maximizing impact in any setting. This comprehensive guide delves into the essence of this product, exploring its market significance, technical intricacies, diverse applications, and the rigorous processes that bring it to life.

Industry Trends and the Evolution of Display Solutions

The global display solutions market is experiencing significant shifts, driven by demands for increased durability, aesthetic versatility, and sustainability. As businesses strive to create more engaging and professional environments, the focus has moved beyond mere functionality to design elegance and material integrity. Modern display holders, like the **T-shape acrylic metal A4 paper holder**, embody this evolution, integrating high-quality acrylic with sturdy metal bases to offer superior stability and a premium look that conventional plastic or pure acrylic stands cannot match.

According to a report by Grand View Research, the global display market size was valued at USD 149.7 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is largely fueled by the increasing adoption of digital signage and point-of-sale (POS) displays, but also a persistent need for tangible, static information displays that are both cost-effective and aesthetically pleasing. The rise of pop-up shops, temporary exhibitions, and flexible office layouts further boosts the demand for easily deployable, robust, and visually appealing display accessories. The integration of durable materials like metal in a product like the **T-shape acrylic metal A4 paper holder** directly addresses the need for long-lasting, reusable display tools that reduce waste and project a professional image.

Enhancing retail aesthetics with a modern **T-shape acrylic metal A4 paper holder**.

Technical Parameters and Material Science Behind the Holder

The performance and longevity of a **T-shape acrylic metal A4 paper holder** are fundamentally dictated by its technical specifications and the properties of its constituent materials. Understanding these parameters is crucial for both manufacturers committed to quality and customers seeking reliable display solutions.

Material Specifications:

- Acrylic (Polymethyl Methacrylate - PMMA): The transparent T-shaped part is typically made from high-grade acrylic, known for its exceptional clarity (light transmittance often exceeding 92%, comparable to optical glass), impact resistance (up to 17 times stronger than glass), and excellent weatherability. This ensures the displayed document remains clearly visible and the holder resists yellowing or degradation over time, even with prolonged UV exposure. Common thicknesses range from 2mm to 5mm, providing a balance between lightness and structural integrity.

- Metal Base (Steel or Aluminum Alloy): The base provides the necessary weight and stability.

- Steel (e.g., Cold Rolled Steel, Stainless Steel): Offers superior strength and weight, making the holder very stable. Often coated (powder coating, chrome plating, or brushed finish) for aesthetics and corrosion resistance. Common gauges (thicknesses) for steel bases range from 1.0mm to 3.0mm depending on desired heft and profile.

- Aluminum Alloy (e.g., 6061-T6): Lighter than steel but still offers excellent strength-to-weight ratio. Often anodized or brushed for a sleek, modern look and enhanced corrosion resistance. Aluminum bases might be slightly thicker to compensate for lower density while maintaining stability.

Product Specifications Table: **T-Shape Acrylic Metal A4 Paper Holder**

| Parameter | Typical Value Range | Unit | Notes |

|---|---|---|---|

| Overall Dimensions (H x W x D) | 310 x 220 x 80 | mm | Designed for A4 paper (210x297mm) |

| Acrylic Thickness | 2.0 - 5.0 | mm | Impact resistance & clarity |

| Metal Base Thickness | 1.0 - 3.0 (Steel); 1.5 - 4.0 (Alum.) | mm | Stability & durability |

| Product Weight | 0.3 - 0.8 | kg | Varies by material and base design |

| Finish (Metal Base) | Powder Coated, Brushed, Chrome Plated, Anodized | N/A | Aesthetic & corrosion resistance |

| Finish (Acrylic) | Clear Polished | N/A | High transparency |

| Certifications | RoHS, REACH (for materials); Internal QC | N/A | Ensures material safety and quality |

| Operating Temperature | -20 to +60 | °C | Suitable for indoor environments |

| Service Life | 5 - 10+ | Years | Under normal indoor conditions |

The elegant gold finish of a **T-shape acrylic metal A4 paper holder** adds a touch of luxury.

Comprehensive Manufacturing Process: Crafting the **T-shape acrylic metal A4 paper holder**

The creation of a high-quality **T-shape acrylic metal A4 paper holder** is a meticulous process that combines advanced manufacturing techniques with rigorous quality control. While not involving heavy industry processes like casting or forging, the precision in cutting, forming, and finishing is paramount. The primary manufacturing processes involve material preparation, precise cutting, forming, surface treatment, assembly, and stringent quality assurance.

Detailed Manufacturing Workflow:

- Material Selection & Preparation:

- Acrylic: High-grade virgin PMMA sheets are selected for optimal clarity and scratch resistance. Sheets are inspected for flaws.

- Metal: Cold-rolled steel sheets or aluminum alloy plates are sourced. Material certificates (e.g., ISO 9001 certified suppliers) ensure chemical composition and mechanical properties meet specifications.

- Precision Cutting (Metal & Acrylic):

- Metal Base: Utilizes CNC laser cutting or precision stamping to achieve the exact base profile. Laser cutting offers high accuracy (tolerances typically ±0.05mm) and clean edges, minimizing post-processing.

- Acrylic T-Shape: Laser cutting or CNC routing is employed for precise dimensions and smooth edges. Laser cutting also "flame polishes" the edges, providing a crystal-clear finish directly from the machine.

(Diagram/Illustration Suggestion: Two parallel lines showing input materials, then arrows pointing to laser cutting machines with schematic representations of the parts being cut out.)

- Forming & Shaping (Metal):

- The cut metal blanks are then precisely bent using CNC press brakes to create the desired T-shape base structure. This ensures consistent angles and dimensions across batches. Multi-axis bending capabilities allow for complex geometries if required for specific designs.

(Diagram/Illustration Suggestion: A metal sheet being fed into a press brake, showing the bending action with an arrow indicating the force.)

- Surface Treatment & Finishing (Metal):

- Deburring & Grinding: Edges are deburred to remove any sharp points or imperfections from cutting.

- Cleaning & Pre-treatment: Metal parts undergo a multi-stage cleaning process (degreasing, rinsing, phosphating) to ensure optimal adhesion for subsequent coatings and corrosion resistance.

- Coating/Plating:

- Powder Coating: Electrostatic application of dry powder, followed by heat curing, creates a durable, even, and aesthetically pleasing finish in various colors. This offers excellent chip, scratch, and corrosion resistance, complying with standards like ASTM D3359 for adhesion.

- Electroplating (e.g., Chrome, Nickel): For a metallic luster, parts are electroplated. This provides a hard, wear-resistant, and corrosion-protective layer.

- Brushing/Polishing: For stainless steel or aluminum, mechanical brushing or polishing achieves a satin or mirror finish.

- Anodizing (Aluminum): An electrochemical process that thickens the natural oxide layer, enhancing corrosion and wear resistance while allowing for vibrant coloring.

(Diagram/Illustration Suggestion: A part moving through various baths for pre-treatment, then into a spray booth for powder coating, followed by a curing oven.)

- Edge Polishing (Acrylic):

- While laser cutting provides good edges, for premium finishes, the acrylic edges may undergo additional flame polishing or diamond polishing to achieve a perfectly smooth, clear, and high-gloss finish, eliminating any minor imperfections or frosted appearances.

- Assembly:

- The finished acrylic T-shape display panel is securely attached to the metal base. This typically involves high-strength adhesive bonding, often UV-cured, which creates a durable, invisible bond, or precision-fit interlocking mechanisms. The assembly process is carefully controlled to prevent air bubbles or misalignment.

(Diagram/Illustration Suggestion: An acrylic part being lowered onto a metal base, with an arrow indicating the bonding process.)

- Quality Control & Inspection:

- Each **T-shape acrylic metal A4 paper holder** undergoes a multi-point inspection process. This includes:

- Dimensional Accuracy: Verification against CAD specifications using calipers and gauges.

- Material Clarity & Finish: Inspection for scratches, blemishes, bubbles, or inconsistent finishes.

- Bonding Strength: Random pull tests or visual checks of adhesive integrity.

- Stability & Balance: Ensuring the assembled unit stands perfectly upright and is stable.

- Packaging Integrity: Final check for proper protection for shipping.

- Compliance with internal quality standards, often mirroring aspects of ISO 9001:2015 for quality management systems, ensures consistent product excellence.

(Diagram/Illustration Suggestion: A magnifying glass icon over a finished product, with checkmarks indicating various inspection points.)

- Each **T-shape acrylic metal A4 paper holder** undergoes a multi-point inspection process. This includes:

- Packaging:

- Each holder is individually wrapped (e.g., in protective film or foam) and packed into cartons to prevent damage during transit. Custom packaging solutions are available for bulk orders.

Durability and sleek design make the **T-shape acrylic metal A4 paper holder** ideal for high-traffic retail environments.

Application Scenarios and Strategic Advantages

The versatility of the **T-shape acrylic metal A4 paper holder** makes it suitable for an extensive range of applications, providing distinct advantages in each setting.

- Retail Environments: From clothing boutiques to electronics stores, these holders are perfect for displaying product specifications, sale promotions, pricing information, or QR codes for online links. Their sturdy base prevents accidental knocks, and the clear acrylic ensures readability.

- Corporate Offices & Lobbies: Ideal for displaying directional signage, visitor information, important announcements, or company mission statements. The sleek design integrates seamlessly into professional aesthetics.

- Restaurants & Cafes: Used for daily specials, menu highlights, table numbers, or special event promotions. The ease of updating content is a significant advantage.

- Hotels & Hospitality: Welcome messages, service directories, Wi-Fi instructions, or local attraction information can be presented elegantly in guest rooms, lobbies, and reception areas.

- Exhibition & Trade Shows: Critical for conveying key product features, company details, or service offerings at booths. Their portable yet robust nature makes them invaluable for temporary setups.

- Educational Institutions & Libraries: Displaying notices, event schedules, course information, or collection highlights. The durability ensures longevity in high-traffic areas.

- Real Estate Agencies: Showcasing property details, open house schedules, or agent contact information. The professional presentation reinforces brand image.

- Medical Facilities: Presenting patient information, wait times, health advisories, or directional signs. Hygiene is also key, and both acrylic and metal are easy to clean and sanitize.

Technical Advantages:

- Enhanced Stability: The robust metal base provides significantly greater stability compared to all-acrylic holders, reducing the risk of tipping over in busy environments.

- Superior Durability: The combination of high-impact acrylic and resilient metal ensures a longer service life, resisting wear, tear, and accidental damage far better than flimsier alternatives.

- Premium Aesthetic: The contrast between the transparent acrylic and the polished or coated metal base creates a modern, high-end look that elevates the perceived value of the displayed content.

- Corrosion Resistance: High-quality metal finishes (powder coating, anodizing) provide excellent protection against rust and corrosion, maintaining appearance over time.

- Ease of Content Update: The open-sided T-shape design allows for quick and effortless insertion or removal of A4 documents.

- Dual-Sided Visibility: The T-shape design inherently allows for content to be viewed from both sides, maximizing exposure.

Seamless integration of the **T-shape acrylic metal A4 paper holder** with existing retail display solutions.

Manufacturer Comparison and Customization Solutions

Choosing the right manufacturer for your **T-shape acrylic metal A4 paper holder** is crucial for ensuring quality, consistency, and value. While many suppliers exist, key differentiators include material quality, manufacturing precision, customization capabilities, and after-sales support.

Key Factors for Manufacturer Comparison:

- Material Sourcing: Reputable manufacturers use verified, high-grade virgin acrylic (not recycled or low-grade) and certified metals. Ask for material data sheets and compliance certificates (e.g., RoHS, REACH).

- Manufacturing Expertise: Look for evidence of advanced machinery (CNC lasers, press brakes), skilled technicians, and robust quality control protocols.

- Customization Options: Can they offer different metal finishes (matte, gloss, brushed, specific colors), acrylic tints, custom dimensions, or logo engraving? A strong manufacturer will provide tailored solutions.

- Lead Times & Production Capacity: Evaluate their ability to meet your volume and delivery requirements, especially for large or recurring orders.

- Pricing & Value Proposition: Compare pricing but consider it in conjunction with quality, durability, and service. Cheaper options often compromise on material or manufacturing standards.

- Certifications & Standards: Does the manufacturer adhere to international quality management systems like ISO 9001? While specific product certifications (like ANSI for displays) might not be universal, internal rigorous testing protocols are indicative of quality.

Customization Solutions for the **T-shape acrylic metal A4 paper holder**:

Beyond the standard clear acrylic and black/silver metal, customization can significantly enhance brand integration and specific functional needs:

- Color Matching: Metal bases can be powder coated to match specific brand colors (using RAL or Pantone codes).

- Material Variants: Options like brushed stainless steel for a more industrial look, or brass/copper finishes for a vintage aesthetic.

- Logo Integration: Laser engraving or UV printing logos onto the metal base or even the lower clear acrylic section.

- Size Adaptations: While A4 is standard, custom holders for A3, A5, or specific brochure sizes can be produced.

- Weight Adjustment: For extremely high-traffic or outdoor (covered) use, heavier bases can be designed for maximum stability.

- Anti-slip Features: Adding rubber feet or felt pads to the base for enhanced grip and surface protection.

- Interactive Elements: Although primarily static, some designs could incorporate small pockets for business cards or NFC tags for digital integration.

The versatile **T-shape acrylic metal A4 paper holder** seamlessly complements diverse store display themes.

Real-World Application Cases and Customer Success Stories

The practical benefits of the **T-shape acrylic metal A4 paper holder** are best illustrated through its successful deployment in various industries. While specific client names might be proprietary, the following generalized case studies highlight the product's impact:

Case Study 1: High-End Fashion Boutique Chain

A chain of luxury fashion boutiques sought a sophisticated yet durable solution for displaying pricing and promotional offers at their cash registers and within display cases. Their previous plastic holders frequently cracked or tipped over, reflecting poorly on their brand image. By transitioning to custom-designed **T-shape acrylic metal A4 paper holders** with brushed gold-finish metal bases, they achieved:

- Elevated Brand Perception: The premium aesthetic perfectly complemented their store's luxurious ambiance.

- Reduced Replacements: The holders proved significantly more durable, leading to a substantial reduction in replacement costs and waste.

- Improved Customer Experience: Stable, clear displays ensured information was easily accessible without distraction.

Case Study 2: National Bank Branch Network

A major national bank required a uniform, secure, and professional way to display interest rates, financial product information, and regulatory notices across all its branches. They opted for the **T-shape acrylic metal A4 paper holder** with a sleek matte black powder-coated base.

- Consistent Branding: Standardized appearance across hundreds of branches reinforced their corporate identity.

- Enhanced Security: The heavy metal base made the holders difficult to accidentally dislodge or move, ensuring critical information remained visible.

- Longevity in High-Traffic Areas: The robust construction stood up to constant interaction in busy branch environments, proving their value over time.

Case Study 3: International Art Gallery & Museum

An acclaimed art gallery and a museum needed unobtrusive yet stable holders for displaying artwork descriptions, artist biographies, and exhibit information. The **T-shape acrylic metal A4 paper holder** with a subtle silver brushed aluminum base was chosen.

- Minimalist Design: The clean lines and transparent acrylic ensured the focus remained on the artwork, not the display mechanism.

- Stability for Valuables: The secure base prevented accidental tipping, crucial in environments with delicate and irreplaceable items.

- UV Protection (Optional): While standard acrylic offers good UV resistance, custom orders with enhanced UV-blocking acrylic further protected printed materials from fading under gallery lighting.

Ensuring Trustworthiness: Quality Assurance, Warranty, and Support

For any B2B purchase, trust is paramount. A reliable supplier of **T-shape acrylic metal A4 paper holder** products demonstrates trustworthiness through transparent quality processes, clear warranties, and accessible customer support.

Quality Assurance & Standards:

Our manufacturing adheres to stringent internal quality control protocols, inspired by international benchmarks such as ISO 9001:2015 for Quality Management Systems. Every batch of raw materials is inspected upon arrival, and in-process checks are conducted at each stage of manufacturing—from laser cutting dimensions to the quality of the powder coating finish and the strength of the adhesive bond. Final product inspection ensures dimensional accuracy, aesthetic perfection, and structural integrity. We conduct load-bearing tests on the assembled units to ensure they withstand typical usage scenarios over their expected service life of 5-10+ years under normal indoor conditions.

Delivery Cycle & Logistics:

Typically, for standard orders of the **T-shape acrylic metal A4 paper holder**, our production lead time ranges from 10 to 20 business days, depending on order volume and current production queue. For customized solutions, this may extend slightly. We work with reliable logistics partners to ensure timely and secure delivery worldwide. Each product is carefully packaged to prevent damage during transit, often utilizing custom-cut foam inserts or individual polybags within sturdy corrugated cartons. Tracking information is provided upon dispatch.

Warranty & After-Sales Support:

We stand behind the quality of our **T-shape acrylic metal A4 paper holder** products. All holders come with a standard 1-year warranty against manufacturing defects from the date of purchase. This warranty covers issues arising from materials or workmanship under normal usage conditions. Our dedicated customer support team is available to assist with any queries regarding product specifications, order status, or after-sales issues. We are committed to ensuring customer satisfaction and building long-term partnerships.

Customer Feedback Spotlight: "We ordered a batch of **T-shape acrylic metal A4 paper holder** units for our new office complex. The quality is exceptional – the metal base is incredibly stable, and the acrylic is crystal clear. They truly elevate the professional look of our reception and meeting areas. The delivery was prompt, and the packaging was excellent. Highly recommended!" - *Sarah L., Office Manager, Global Consulting Firm*

Professional FAQ: In-Depth Insights on the **T-shape acrylic metal A4 paper holder**

Q1: What is PMMA, and why is it used for the acrylic component of the **T-shape acrylic metal A4 paper holder**?

PMMA stands for Polymethyl Methacrylate, commonly known as acrylic glass. It's a transparent thermoplastic renowned for its outstanding clarity, often exceeding 92% light transmission, making it clearer than standard glass. It's also significantly more impact-resistant than glass (up to 17 times) and much lighter. For a **T-shape acrylic metal A4 paper holder**, PMMA ensures that displayed documents are highly visible and protected, resists yellowing from UV exposure, and offers durability against minor impacts, crucial for a long-lasting display solution.

Q2: What are the common metal types and finishes for the base, and what are their advantages?

The most common metal types for the base are cold-rolled steel and aluminum alloy. Steel offers superior weight and rigidity, enhancing stability, and is often finished with durable powder coating (for various colors and excellent scratch/corrosion resistance) or chrome plating (for a shiny, mirror-like finish). Aluminum alloy is lighter but still very strong, ideal for portable displays, and is commonly finished with anodizing (for enhanced corrosion resistance and a range of metallic colors) or brushing (for a sophisticated matte texture). Each finish provides specific aesthetic and functional benefits tailored to different environments.

Q3: How is the acrylic part securely attached to the metal base?

The acrylic T-shape display is typically attached to the metal base using a strong, transparent, and often UV-cured adhesive bond. This method creates a seamless and highly durable connection that is virtually invisible, preserving the aesthetic appeal of the holder. The bonding process is carefully controlled to prevent air bubbles and ensure maximum adhesion strength, making the integrated **T-shape acrylic metal A4 paper holder** a robust single unit.

Q4: Can the **T-shape acrylic metal A4 paper holder** be used outdoors?

While the acrylic component has good UV resistance, the **T-shape acrylic metal A4 paper holder** is primarily designed for indoor use. Prolonged direct exposure to harsh outdoor elements (e.g., extreme temperatures, heavy rain, strong winds) could potentially reduce its service life, cause fading of the displayed paper, or affect the metal finish over extended periods. For covered outdoor areas like patios or semi-enclosed exhibition spaces, they may perform adequately, but constant direct exposure is not recommended.

Q5: What are the typical dimensions for the A4 paper slot, and can custom sizes be made?

The standard A4 paper size is 210mm x 297mm (8.27 x 11.69 inches). Therefore, the slot of the **T-shape acrylic metal A4 paper holder** is designed to comfortably accommodate these dimensions, typically with a slight allowance (e.g., 215mm width). Yes, custom sizes can certainly be made. Manufacturers often offer bespoke solutions for other paper formats like A3, A5, letter size, or specific brochure dimensions, requiring adjustments to the acrylic and base components.

Q6: How does the weight of the metal base contribute to the holder's functionality?

The weight of the metal base is crucial for the overall stability and anti-tipping functionality of the **T-shape acrylic metal A4 paper holder**. A heavier base lowers the center of gravity, making the holder less prone to accidental knocks or disturbances in high-traffic environments. This prevents the display from falling over, ensuring that information remains visible and presenting a professional, secure appearance, especially important for counter-top displays.

Q7: What is the estimated service life of a high-quality **T-shape acrylic metal A4 paper holder**?

A high-quality **T-shape acrylic metal A4 paper holder**, manufactured with premium materials and precision processes, typically has an estimated service life of 5 to 10+ years under normal indoor conditions. Factors contributing to this longevity include the inherent durability of PMMA acrylic (resistance to yellowing, impact), the robust construction of the metal base, and the quality of its protective finish (e.g., powder coating), which resists corrosion and wear.

Industry Insights & Further Reading

- Display Market Analysis: Grand View Research. "Display Market Size, Share & Trends Analysis Report By Technology, By Application, By Region, And Segment Forecasts, 2023 - 2030." Available at: https://www.grandviewresearch.com/industry-analysis/display-market

- Acrylic Properties: Perspex International. "What is Acrylic?" Learn more about the material properties. Available at: https://www.perspex.co.uk/what-is-perspex

- Powder Coating Benefits: The Powder Coating Institute. "Benefits of Powder Coating." Providing detailed information on this durable finishing process. Available at: https://www.powdercoating.org/page/WhyPowderCoat

- Retail Display Trends: National Retail Federation (NRF) insights on visual merchandising and store design, frequently discussing the importance of physical displays. Explore their articles and reports at: https://nrf.com/blog/topic/store-design-visual-merchandising

-

Comprehensive Guide to Retail Store Fixtures – Trends, Benefits & Innovations

NewsNov.24,2025

-

Premium Store Display Fixtures - Durable & Sustainable Retail Solutions

NewsNov.23,2025

-

Your Expert Guide to Store Fixture Shops – Design, Sustainability & Trends

NewsNov.23,2025

-

Discover the Flexibility of Pop Up Shop Fixtures – Modular Display Solutions for Every Need

NewsNov.22,2025

-

Enhance Your Retail Space with Premium Golf Shop Display Fixtures | Durable, Customizable Solutions

NewsNov.22,2025

-

Premium Golf Shop Fixtures for Modern Retail | Durable & Customizable Displays

NewsNov.21,2025